It is known as the strength of the material. There are two objectives, The first is to determine the stress that acts on the surface of volume elements of critical points of loaded structures. Secondly, To aid in the design and analysis of the structures, it also establishes equivalent stresses based on strength requirements linked to potential failure modes.

Also, A field of study

in engineering and physics called mechanics of materials. It is an essential area of study for engineers

and is necessary for the design and analysis of mechanical parts and

structures.

These are some essential ideas and notions in material mechanics.

Stress:

Stress is a measurement of a material's internal resistance to deformation in the presence of an external force. It usually has units of Pascals (Pa) and is represented as force per unit area. The stress calculation formula as below.

There are a few types of stress.

Tensile Stress:

Tensile stress is the stress that develops when an axial load tries to elongate or stretch a material. It is computed by dividing the applied force by the area of the cross-section.

Compressive Stress:

An axial load that attempts to compress or shorten a material will cause compressive stress, which is the opposite of tensile stress.

Shear Stress:

Shear stress is the important parameter in various fields. Shear stress is an internal resistance within a material when subjected to forces that cause one layer or portion of the material to slide or deform relative to an adjacent layer.

Mathematically, shear stress is defined as:

τ = F / A

Where:

τ (tau) is the shear stress in pascals (Pa) or other appropriate units.

F is the force applied parallel to the material's surface.

A is the cross-sectional area over which the force is applied.

Bearing Stress:

Bearing stress occurs when two materials are in contact, and the force is applied perpendicular to the surface. It is the force divided by the contact area.

Strain:

Strain is a measure of the deformation or change in shape that a material undergoes when subjected to an external force or load. It is frequently described as the variation in length or shape from the initial length or shape. Dimensionless, strain is classified into two types: shear strain, which comes from shear stress, and axial strain, which comes from normal stress.

Depending of the nature application, there are different types. Such as compressive strain happens when applying compressive forces, tensile strain occurs when applying stretching forces, and simple shear strain occurs when forces act parallel to each other but in opposite directions, causing a material to deform without changing its volume.

Young's Modules:

Under axial load, a material's resistance to elastic deformation, or reversible deformation, is expressed by its Young's modulus (E). It uses the relationship between stress and strain to describe the stiffness of a material.

Hooke's Law:

This is described that linear relationship between the strain of the material (deformation) and applied force inn elastic region of the material. , it asserts that stress and strain are directly proportionate.

Where,

F is Spring Force

k is spring constant

x is spring stretch or compression

Yield Strength:

The point at which a material experiences permanent deformation or yielding is known as the yield strength. This is in contrast to the ultimate strength. A material's ultimate strength is the highest stress it can bear before failing.

Yield strength is relevant for ductile material. In contrast, brittle material is not showing the significant plastic deformation before facture. In brittle materials, there is no distinct yield point or yield strength. Instead, they have a linear or nearly linear elastic region in their stress-strain curve up to the point of fracture.

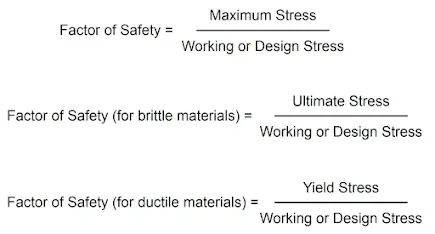

Factor of Safety:

A structure or component's ability to support loads with a margin of safety is determined by using the factor of safety in engineering design. It is the ratio of the material's ultimate strength to the highest load that can be anticipated.

Torsion:

When an object is subjected to a torque or twisting force, it will twist or rotate, a phenomenon known as torsion in mechanics. An essential idea in mechanics and engineering, torsion is especially important when examining how structural elements that undergo twisting loads, such as beams, shafts, and other components.

A material deforms when it is subjected to torsional force, and this deformation is characterized by a change in rotational angle. Shear strain which is defined as the change in angle per unit length of the material, is a notion that describes this deformation. Shear stresses in the material as a result of torsional deformation are what cause the material to resist an applied torque.

The fundamental equation that relates these parameters in the context of torsion is:

τ = T * r / J

Where:

τ is the shear stress,

T is the applied torque,

r is the radial distance from the center of rotation (distance from the axis of rotation to the point of interest)

J is the polar moment of inertia.

Bending:

A combination of axial and transverse loads can cause a structural element to bend.

There are two types of bending,

Flexural Bending (or simply Bending):

The most frequent kind of bending is called flexural bending, which happens when a material or structural element is subjected to a load or force that is delivered perpendicularly, causing the material or structural element to deform and curve. Beams, rods, and sheets that bend are common examples.

Shear Bending (Torsional Bending):

Shear bending, sometimes referred to as torsional bending, is the result of rotating or twisting forces causing a material to deform in a curved direction.

The formula for bending,

σ = (M * c) / I

Where:

σ is the bending stress

M is the bending moment

c is the distance from the neutral axis to the outermost fiber of the material

I is the moment of inertia of the material's cross-sectional shape.

In conclusion, The design, analysis, and safety of mechanical components and structures in many engineering specialties, including civil, mechanical, and aerospace engineering, rely significantly on the concepts of materials mechanics. Engineers utilize these principles to ensure that materials and constructions are strong enough to handle expected loads and perform as intended.

.webp)

0 Comments: