Forming is the one of manufacturing methods which is used to make some objectives. Metal forming is the metalworking process that is used to form metal parts for different shapes through deformation. The material piece is reshaped without adding or removing material.

Hot Forming

The hot hot-forming process is used very frequently to cast industrial products and parts. The

raw materials are available form of sheets, tubes, bars or wire. In this process,

heat is applied to the material to soften. Then, some of the required pressure is

applied to get the desired shape of the metal. This process is also capable of forming a variety of complex parts and holds relatively tight tolerances.

Most hot-forming processes are complex due to the involvement of adiabatic heating, die chill

and microstructural changes.

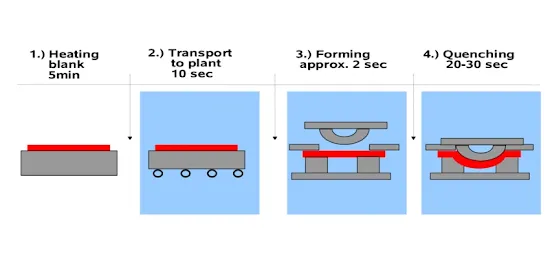

Hot

hot-forming process is one of sheet forming processes of sheet metal. This process

is also known as hot stamping or press hardening. All forming processes are run

above the recrystallization temperature of the material. The material recovers

and softness during the hot forming process of sheet metal. The hot sheet metal

is brought into contact with the hot die and a hot punch is pressed into the die to form

the shape and then apply forming pressure for a period.

A direct (one-stage) hot-forming process is commonly used due to forming and part hardening

being done in one operation.

|

Advantages of hot forming |

Disadvantages of hot forming |

|

Accurate forming |

Burr formation |

|

Complex shapes |

Furnaces cause high energy cost |

|

Consistent thickness |

The surface finish is poor |

|

Higher surface profile tolerances |

The component can wrapped in the worst-case |

|

Resistance to cracking |

The surface of the component

slightly scaled due to the high working temperature |

|

Good strength |

|

|

Lower cost |

|

|

Low spring back |

|

The uses of the hot-forming process are as below,

In the automobile industry: -

Side members, door reinforcements, sills, roof frames, roof

rails, and bumper supports.

Cold Forming

The cold forming process is the metal forging

process at bear room temperature or slightly above room temperature. Forming

metal at cooler temperatures may retain or enhance the tensile strength of the

material. This process is a high-speed process that allows the manufacture of large

amounts of metal-based products in a fast, consistent and cost-effective way. Cold-formed parts have greater yield, higher

tensile strength and superior surface finish when compared to hot-formed parts.

The cold-forming process can be classified into

four major groups, such as squeezing, bending, drawing, and shearing. However,

higher loads are required to do the cold forming process and deformation is low compared hot forming process. Also, a high degree of manufacturing experience is

required to achieve complex geometry parts.

|

Advantages of Cold-forming |

Disadvantages of Cold forming |

|

No heat is required, so low energy is required |

Harder tools and dies are needed due to metal is

harder |

|

Better surface

finish |

Low

deformation |

|

Superior

dimensional accuracy |

Material with

low ductility cannot be sold formed. |

|

Improve

strength properties |

Metal surfaces

must be clean and scale-free |

|

Contamination

problems are minimized |

Residual

stress may occur |

|

Material

savings & elimination of scrap |

Higher forces

required for deformation |

|

Inexpensive |

|

|

Big production

rate and long life |

|

|

Material

savings & elimination of scrap |

|

Fasteners, screws, nuts, bolts, electrical

contacts, and rivets

Warm Forming

Warm forming is the metal deform process in which metal is heated to a temperature that maximizes the material's malleability without allowing re-crystallization, grain growth, or metallurgical fracture. Warm forming aims to combine the strong points of hot and cold forming. Better surface finishes can be achieved than hot forming. Temperature control is difficult in this process. If more complex parts are formed, precision is low. The warm-forming process is suitable for medium-scale productions.

|

Advantages of Warm forming |

Disadvantages of Warm forming |

|

Reduce tooling loads

compared to cold-forming |

Lower precision than cold forming

|

|

Increased

steel ductility |

Strict temperature control |

|

Lesser amount of heat energy requirement than hot forming |

Greater press loads than hot forming |

|

Lesser thermal

shock on tooling than hot forming |

Required

skilled engineering to design appropriate tooling |

|

Better dimensional control than hot forming |

|

|

Better

precision components than hot forming |

|

In the automotive industry,

warm-formed parts are used (Door panels, fenders). In such applications, warm

forming of certain aluminium alloys may be cost-effective because of reduced

vehicle weight and fuel consumption.

.webp)

0 Comments: