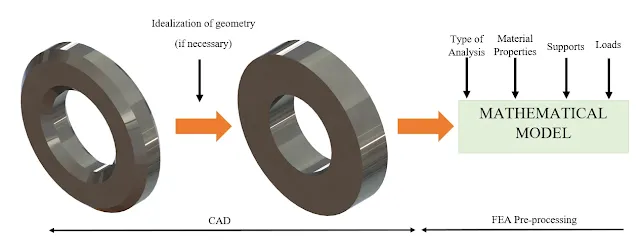

In mechanical engineering, FEA is widely used to solve problems related to structural, vibration, and thermal problems. There are other numerical solution analysis tools, such as the Finite Difference method, Boundary Element Method or Finite Volumes Method. However, FEA became a common tool due to its versatility and high efficiency. The FEA method can be used to solve problems ranging from very simple to very complex. Mechanical design engineers use often it in the design stage. The basic phases in each FEA project are always the same, regardless of the project's complexity or area of application. The geometric model is the starting point for any analysis. In SolidWorks, a SolidWorks part or assembly is a geometric model containing applicable material properties, loads, and restrictions.

The model is discretized (meshed) for the analysis. The geometry is divided into relatively small and simple-shaped entities known as finite elements throughout this procedure. The elements are referred to be finite to indicate that they are not infinitesimally small, but rather reasonably small in respect to the overall model size.

Each FEA application requires three steps,

Preprocessing:

The type of analysis, material properties, loads and restraints are defined and the model is split into finite elements.

Solution:

Computing the desired results.

Postprocessing:

Analysis of the results.

There are four main steps in the FEA methodology,

Building the mathematical mode:

The geometric shape is represented by a SolidWorks part or assembly. Then model is meshed into correct and reasonably small, finite elements. This meshing process is very important because good mesh geometry provides the correct solution for the data of interest, such as stress, displacements, and etc.

Defeaturing:

This is called simply the geometric model by removing or suppressing features which are insignificant to analysis. As an example, removing thread features, and logos.

Idealization:

The process of reducing a real structure to a collection of finite elements. At its most basic, the operation would consist of a single CAD-generated geometric model that is fully meshed in a single operation.

Clean-up:

This is required but not always. This process is used to maintain the higher quality requirements. CAS quality-control tools can be used to check for any problems. Such as multiple entities or sliver daces.

Build a Finite Element Model

After completing the finite element model, a solver in Solidworks simulation is used to get the desired results.

Analysis Results

Errors in FEA

The process of the FEA introduces unavoidable errors while creating mathematical models and discretizing. such as modelling errors (idealization errors) in the formulation of mathematical models discretization errors in the meshing process and numerical errors in solutions.

Only discretization error applies to FEA. Therefore, discretization errors can be controlled using FEA methods. modelling errors can be controlled by correcting the model before the FEA. Solution errors are difficult to control because they come from the solver.

0 Comments: