The fundamental process of forging involves applying compressive forces to the workpiece using a variety of dies and tools. Hammering metal with stone tools is one of the most ancient and significant metalworking processes used to create jewellery, coinage, and other items. Large turbine rotors, gears, bolts and rivets, cutlery, hand tools, countless structural pieces for machinery, aeroplanes, and trains, as well as an assortment of other transportation equipment are examples of forged parts nowadays.

Blacksmiths have historically used a strong hammer and an anvil to accomplish simple forging operations. But most forgings need tools like a press or a powered forging hammer, along with a set of dies.

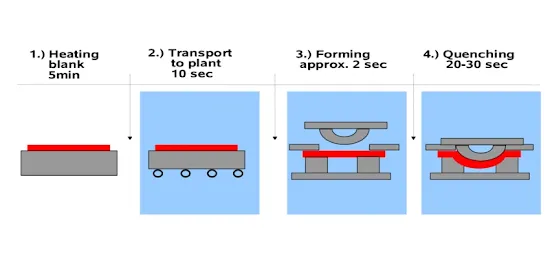

Depending on the homologous temperature, forging can be done at room temperature (cold forging) or at higher temperatures (warm or hot forging). Because the workpiece material is stronger, cold forging requires higher forces, and the material must be sufficiently ductile at room temperature to allow for the required deformation without cracking. Cold-forged parts have accurate dimensions and a fine surface quality. Although hot forging uses less force than cold forging, the components' surface finish and dimensional accuracy suffer as a result. Additional finishing processes, like heat treatment to change characteristics and machining to get precise final dimensions and a smooth surface, are typically applied to forgings. Precision forging, a key example of net-shape or near-net-shape, can reduce these finishing processes. When a material is forged, it is distorted by an impact load or a steady load. Forging is categorized as press forging or hammer forging depending on the kind of loading. Press forging includes progressive stresses, whereas hammer forging involves impact loads.

Open Die Forging

|

Advantages of Die forging |

Disadvantages of Die forging |

|

Products are with greater strength |

Less accuracy

and tolerances |

|

Fatigue

resistance of the parts improved Reduce voids |

Need to machine parts to get the desired accuracy and features. |

|

Capable of producing very large parts which weigh about 136 metric tonnes. |

Applications of Open die forging |

|

Less material

wastage |

|

|

Products have fine grain size and continuous grain flow |

|

Closed Die Forging

|

Advantages of Closed forging |

Disadvantages of Closed forging |

|

Reduce or no machining |

No economic to small or short production runs

due to the high cost of die |

|

Less or no

machining is required for its close tolerances |

High setup cost for furnace dies and machines |

|

Dimension with

tight tolerances part can be made |

Closed die forming is a dangerous process |

|

Better surface

finish and mechanical properties |

|

|

Cost-effective

for large production runs |

|

.webp)

.webp)

Follow Us