Microelectromechanical system (MEMS)

MEMS (Microelectromechanical system) is used to integrate with devices and systems that combine mechanical and electrical items. Integrated circuit (IC)

batch processing techniques are used to fabricate the MEMS systems and they range from micrometres to millimetres. MEMS systems can control

and actuate on the micro-scale and generate effects on the macro scale.

MEMS is called Microsystems Technology (MST) in Europe and Micromachines in Japan. MEMS are

fabricated through a micromachining process while silicon and other substrates

are manipulated sophisticatedly. Bulk and surface micromachining and high aspect ratio micromachining

(HARM) processes are

used to remove parts of the silicon or add additional structural layers to form

the mechanical and electromechanical

components. Therefore, MEMS shows either the mechanical

properties of silicon or both electrical and mechanical

properties.

Figure 1: Schematic illustration of

MEMS

Generally, microsensors, microstructures, microelectronics, and microactuators are integrated

into one silicon chip.

Microsensors: -

Detect the changes in the system’s environment, such as thermal, mechanical,

magnetic, chemical, and electromagnetic information.

Microelectronics:

- The detected changes are processed by microelectronics and give the signal to

microactuators to react and create a re-change to the environment.

MEMS components

are usually very small and microscopic. But MEMS is not just about the mechanical

components miniaturization process. Although, MEMS can be identified as a manufacturing process which is used to design and create complex

mechanical devices and systems and their electronics. The batch fabrication technique

is used for the MEMS manufacturing process. As an example, gears, levers,

motors and steam engines are manufactured.

The size of MEMS

components is between 1-100 µm and

MEMS sensors are generally classified as the range in size 20 µm-1 to mm.

Nanoelectromechanical systems (NEMS)

Nanoelectromechanical systems are denoted as NEMS. This is the technology that can

be used to integrate electrical and mechanical functions in Nanoscale. NEMS

are the next logical miniaturization step from the microelectromechanical system

(MEMS). NEMS are fabricated using a micromachining process. NEMS are very small

and hundreds of NEMS devices can be installed in one space of microdevice that

performs the same functions.

NEMS is also

integrated with sensors, electronics, actuators, photonics, energy, fluidic,

chemistry and biological systems that are enabled by sub-micrometre and

engineering precision.

NEMS technology

is currently used in low and medium-volume applications.

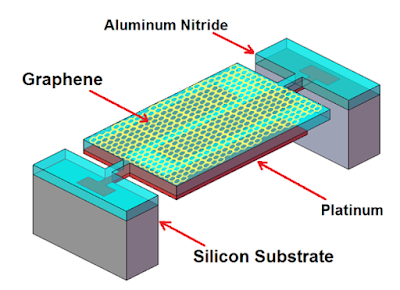

Figure 2: Aluminum Nitride Piezoelectric NEMS devices using 2-dimensional Electrode Material

This is interesting article. Great Job

ReplyDeleteAwesome and interesting article. Great things you've always shared with us. Thanks. Just continue composing this kind of post. Edge Rounding Deburring Machines.

ReplyDeleteI’d like to thank you for writing on this topic. The information you provided was very useful. I will visit again in the near future. Black Light Absorbing Coatings Material.

ReplyDelete